Chainmail, a centuries-old armor innovation, is making a surprising comeback—not on the battlefield, but in the realm of cutting-edge science. Researchers at Northwestern University have developed a groundbreaking two-dimensional (2D) nanomaterial inspired by the interlocking design of chainmail. This invention combines extraordinary strength with flexibility and has the potential to redefine lightweight protective materials such as body armor.

This modern version of chainmail isn’t made of metal links but rather a network of mechanically interlocked polymers. Each square centimeter of this material contains an astounding 100 trillion mechanical bonds, the highest density ever achieved. Despite this complexity, the material is scalable and could revolutionize applications requiring durability and toughness, such as ballistic protection.

A New Era of Polymers

The project builds on decades of innovation, originating from the pioneering work of Sir Fraser Stoddart, a Nobel laureate who introduced the concept of mechanical bonds in the 1980s. Stoddart’s groundbreaking methods allowed molecules to interlock mechanically, laying the foundation for nanomachines and, ultimately, this new material. Northwestern chemist William Dichtel, along with his team, paid homage to Stoddart by dedicating their research to his memory.

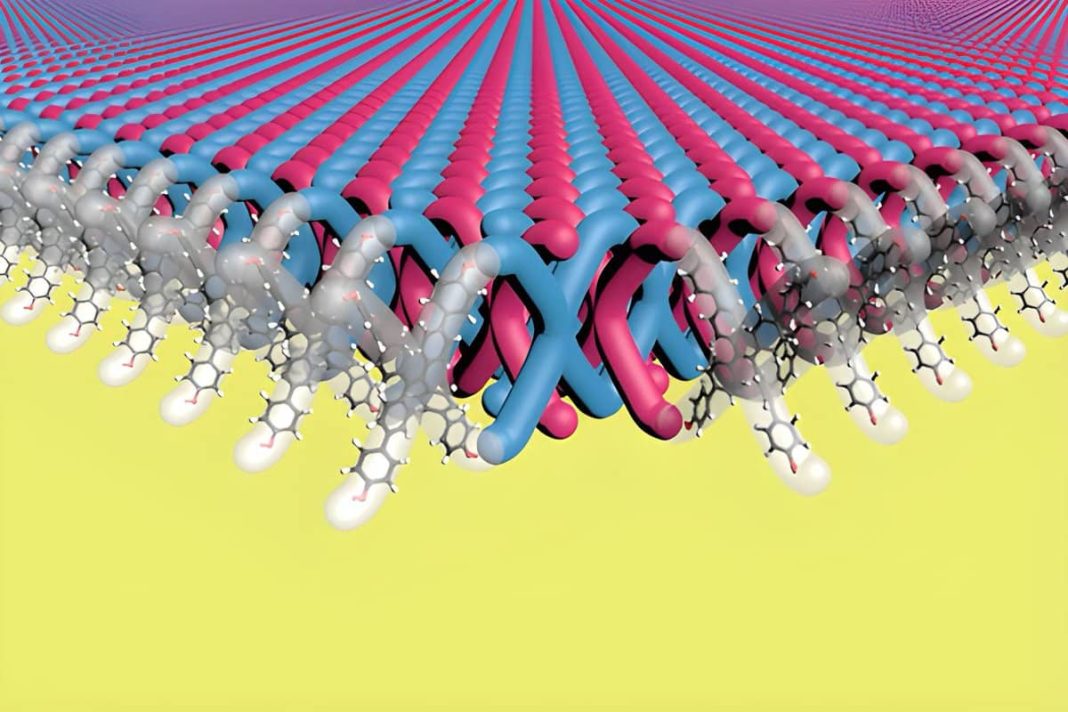

The creation process begins with X-shaped monomers, which are arranged in a precise crystalline structure. These monomers are chemically bonded to one another, and additional monomers are threaded through the gaps, forming an interlocked 2D structure. Despite its rigidity, the material remains flexible, a characteristic that allows it to dissipate forces efficiently.

“Think of it like traditional chainmail,” Dichtel explains. “It’s tough to rip because the mechanical bonds slide and distribute force in multiple directions. Breaking it apart would require severing countless points at once.”

A Material with Limitless Potential

The researchers’ method isn’t just innovative; it’s also scalable. While previous attempts to create polymers with mechanical bonds resulted in tiny samples, this team produced half a kilogram of the material—a milestone that opens doors for mass production.

In collaboration with Duke University, the material was incorporated into Ultem, a high-performance polymer known for its strength and heat resistance. Adding just 2.5% of the 2D polymer significantly enhanced Ultem’s strength and toughness, demonstrating its potential as a composite material for high-stakes applications.

Looking Ahead

This novel material has sparked excitement across multiple disciplines. Its exceptional strength and lightweight properties make it a strong candidate for future use in body armor, ballistic fabrics, and even aerospace applications. While much research remains to be done, the initial results suggest that this nanomaterial could outclass current protective materials.

“We’ve only scratched the surface of its capabilities,” Dichtel remarks. “Every property we’ve tested has exceeded expectations, and we’re eager to see where this material can take us.”

By marrying ancient design principles with modern chemistry, Northwestern’s researchers have ushered in a new era of materials science. This 21st-century chainmail isn’t just a nod to the past—it’s a bold step into the future.